In our dedication to sustainability and Plasman’s climate-neutral commitment, Plasman Tecumseh and Tilbury Manufacturing have saved 22 million gallons of water through their collective Water Savings Project.

The Water Savings Project began at Tilbury Manufacturing and was adopted by Tecumseh Manufacturing within their pre-paint wash stages. Both plants were able to eliminate city water feeds that were being used to maintain water levels at different stages.

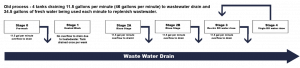

Within our North American paint plants, we wash parts in a five-stage power wash system to ensure parts are free of chemicals, oils, and other contaminants from the molding process, handling, and storage before they are painted. Previously, the pre-wash cycle would pump in gallons of city water every minute into multiple stages of the process, with the same amount of water going straight to drain.

Past Process at Tecumseh Manufacturing

How Two Paint Plants Saved 22M Gallons of Water

Through the installation of troughs and some plumbing between stages, both plants were able to eliminate the city water feed going into multiple stages and use the overflow from one stage to feed the next by travelling through the trough.

Tilbury Manufacturing’s Solution

“We looked at every stage of our power wash that was using city water to blow down and we eliminated it,” said Stephen Lanoue, Maintenance Superintendent, Tilbury Manufacturing.

Initially started in December 2020, Tilbury Manufacturing installed a trough from Stage 3 to Stage 2B to eliminate the city water fill from Stage 2B by using the overflow water from Stage 3, which eliminated 10 gallons/minute of city water.

They then eliminated the city water feed at Stage 0 of four gallons/minute by plumbing over from Stage 2A to feed the overflow water to Stage 0.

From Stage 4, they also eliminated the wastewater from the RO (reverse osmosis) process by plumbing it back to their paint pit. The paint pit loses water daily through evaporation and exhaust stacks, so by plumbing the reject water from Stage 4 to the pit, they were able to eliminate the waste at Stage 4 and the need for a city water feed to maintain the pit water level.

“Stage 2B saved 10 gallons a minute and the sludge pit saved six gallons per minute,” said Stephen. “When you add them all up it’s about 3.34 million gallons of water annually.”

After the success of the project at Tilbury Manufacturing, the team at Tecumseh Manufacturing adopted the process for both their paint lines.

Tecumseh Manufacturing’s Solution

“What we had to do was look at how can we take our old power wash system and modify it to be able to reuse the water instead of it going to waste,” explained Richard Brooke, Operations Manager, Tecumseh Manufacturing.

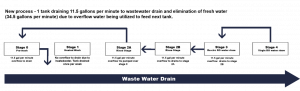

On A Line, through the installation of troughs from Stage 3 to Stage 2B to Stage 2A to Stage 0, they have eliminated the need for a city water feed of 11.5 gallons per minute each on three of their tanks by recycling overflow water that originally went to drain. Now, the only water going to drain is 11.5 gallons/minute at Stage 0. This has saved 35,190 gallons of water usage in a 17-hour production day.

New Process at Tecumseh Manufacturing

Stage 4 of the process is a RO system that runs the city water through a bank of filters that removes salts, minerals, and chemicals from city water to produce the cleanest possible water. This is then filtered down through the stages as overflow water.

“Being able to eliminate the city water going to Stage 2A, Stage 2B, and Stage 0, we can now use reused RO water which is a higher quality of water in each stage that improves the wash and the quality of the part,” said Richard.

B Line presented more of challenge for the team as the layout of the stage is u-shaped and not linear like A Line and there was not a tank at Stage 0 to collect water. They completed B Line in two phases. The first, completed at the end of April 2023, added troughs from Stage 3 to Stage 2B to Stage 2A. By the end of 2023, they had installed a tank to capture the overflow water from Stage 2A and discharge from the RO system and, using a pump and series of pipes, designed a system to pump the water from the tank over to Stage 0 to use 100% recycled water.

Driving Innovation and Sustainability

As Plasman drives toward climate neutrality in 2028, it is projects and innovative thinking like this from our team that contribute to Plasman’s goal of creating a better, more sustainable future.

“For every project that we do, if it’s improving the efficiency of the plant and the process, then there’s energy savings,” said Richard. “And if there’s energy savings it contributes to our sustainability as a plant.”

About Plasman

Plasman is a leading global manufacturer in bumpers-fascias, grilles, exterior trim, and subsystem components. As One Driving Force™, our diverse team of talented employees in 11 countries is driven by a commitment to outperform in all areas from engineering design to state-of-the-art manufacturing processes. Plasman’s headquarters are in Oldcastle, Ontario. Further information about Plasman is available at Plasman.com or follow us on LinkedIn.